Exploring the Crucial Features of Metal Core PCBs

Printed Circuit Boards (PCBs) play a vital role in the functionality and performance of electronic devices. While traditional PCBs are widely used, certain applications require specialized PCBs that can handle high heat dissipation, offer improved thermal management, and enhance overall performance. Enter Metal Core PCBs (MCPCBs), a unique type of circuit board that offers a range of advantages over conventional alternatives. In this blog post, we will delve into the world of metal core PCB, exploring its features, benefits, and applications.

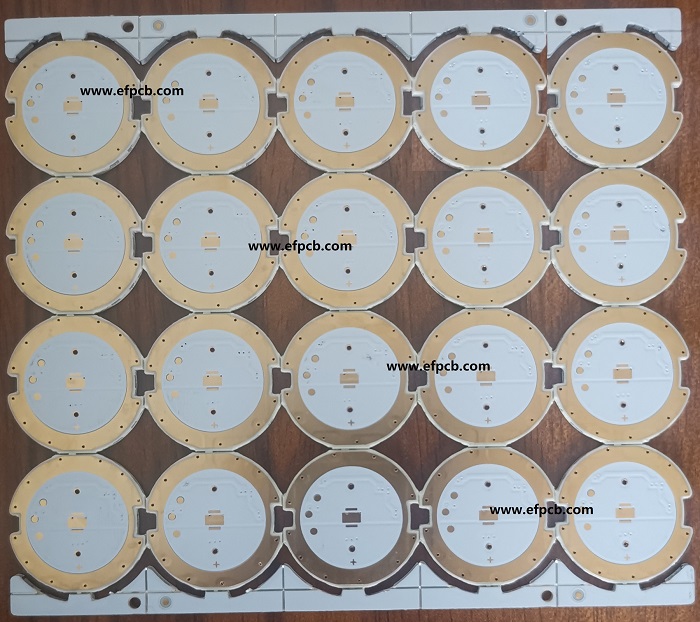

Metal Core PCBs, also known as Metal Backed PCBs or Thermal PCBs, are a specialized type of circuit board that incorporates a thermally conductive metal core layer in addition to the standard layers of a PCB. The metal core is typically made of materials such as aluminum (AL), copper (Cu), or a combination of both.

Features and Benefits

Enhanced Heat Dissipation: One of the key advantages of Metal Core PCBs is their superior ability to dissipate heat. The metal core layer acts as a highly efficient conductor, allowing the rapid transfer of heat away from heat-generating components. This feature makes MCPCBs ideal for high-power applications that require effective thermal management, such as power supplies, LED lighting, automotive electronics, and industrial equipment.

Mechanical Strength and Durability: The metal core in MCPCBs adds mechanical strength and rigidity to the circuit board. This makes them more resistant to physical stress, vibrations, and impacts compared to standard FR-4 PCBs. The improved durability makes MCPCBs suitable for applications that require robustness, such as aerospace, automotive, and military electronics.

Compact Design and Size Reduction: Metal core PCB enables compact designs by eliminating the need for additional heat sinks or cooling devices. The efficient heat dissipation properties of MCPCBs allow for higher component densities, reducing the overall size of the electronic device. This is particularly advantageous for devices where space is a constraint.

Electromagnetic Interference (EMI) Shielding: The metal core layer in metal core PCB acts as a natural shield against electromagnetic

interference. This helps in reducing EMI radiation, improving signal integrity,

and minimizing the risk of cross-talk or electromagnetic compatibility (EMC)

issues.