Why Hydraulic Hoses Quietly Decide Success or Failure

A stalled machine on a busy production floor can cost more than time; it can disrupt entire operations and damage trust. Behind many of these systems lies a component often overlooked until failure occurs: the hydraulic hose. This article explores how dependable hose solutions support industrial stability, why quality sourcing matters, and what separates ordinary products from long-lasting ones. The main focus centers on the role of a trusted hydraulic hose supplier in maintaining safety, efficiency, and performance across demanding applications worldwide.

Understanding the Role of a Professional Hydraulic Hose Supplier

Industrial systems rely on precision, and that precision begins with sourcing. A professional hydraulic hose supplier provides hoses engineered to handle pressure, temperature, and environmental stress without compromise. In the middle of this supply chain, quality assurance and material traceability play a critical role in reducing downtime. Choosing the right partner ensures compatibility with machinery standards while supporting long-term operational reliability. Industries such as construction, manufacturing, and energy depend on consistent hose performance to keep equipment functioning smoothly every day.

Quality Standards and Testing That Define Long-Term Performance

Behind every durable hose is a rigorous process of testing and certification. In this context, a dependable hydraulic hose supplier evaluates products against international standards for pressure resistance, flexibility, and abrasion tolerance. These evaluations, conducted in controlled environments, simulate real-world stress conditions. Midway through production, inspection protocols help eliminate defects before deployment. Such attention to detail improves safety outcomes and protects costly equipment, reinforcing why verified quality controls remain essential across industrial hydraulic systems.

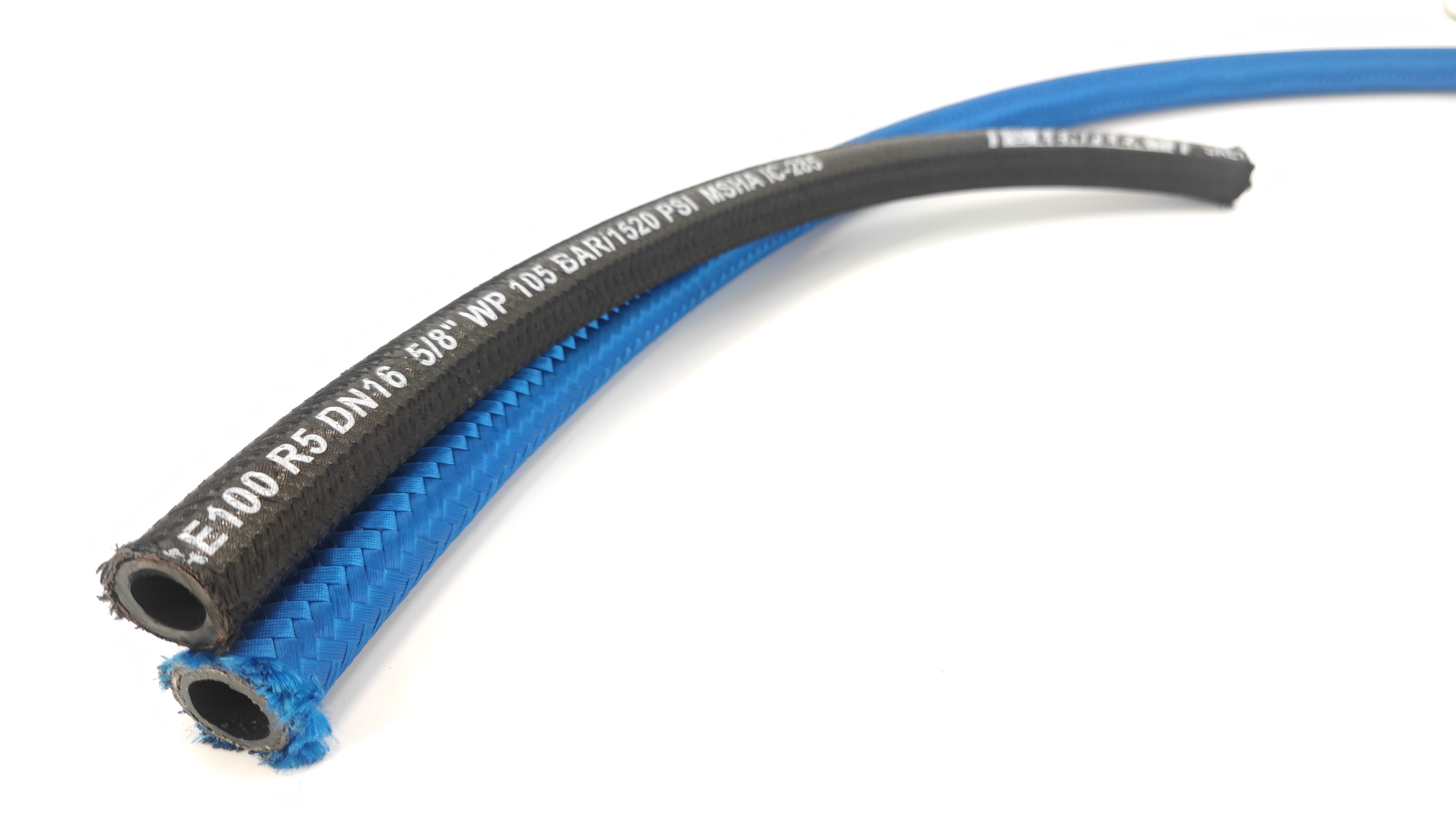

Materials, Engineering, and Application-Specific Design

Hydraulic hoses vary widely based on application, fluid type, and operating pressure. Engineers select rubber compounds, reinforcement layers, and fittings to match exact use cases. In the center of this process lies customization, where a custom hydraulic hose can be designed to fit unique spatial constraints or performance demands. This tailored approach reduces installation errors and extends service life. Precision engineering ensures hoses perform consistently, even in harsh environments involving vibration, heat, or chemical exposure.

Why Customization Matters in Complex Hydraulic Systems

Modern machinery rarely follows a one-size-fits-all design. A custom hydraulic hose becomes essential when standard assemblies fail to meet specific operational requirements. Mid-paragraph considerations include bend radius, length accuracy, and pressure ratings tailored to each system. Customization improves efficiency by minimizing stress points and leakage risks. As industrial systems evolve, the demand for application-specific hose solutions continues to grow, supporting safer operations and smoother performance across diverse sectors.

Global Supply Capabilities and Consistent Manufacturing Practices

Industrial buyers increasingly seek partners capable of supporting international operations with consistent quality. Beyond engineering expertise, global logistics and scalable manufacturing ensure timely delivery. At this stage, collaboration with platforms such as yiqiaogroup.com helps bridge technical requirements with dependable supply chains. In the conclusion of this discussion, the value of working with yiqiaogroup.com stands out for organizations seeking reliable sourcing and engineered hose solutions aligned with global industry expectations.